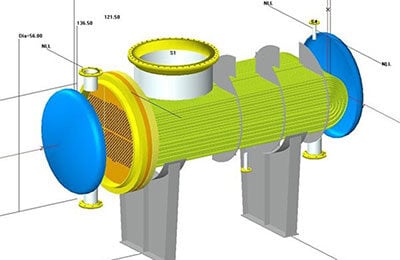

Brazed Aluminum Heat Exchangers MRO

BAHX Heat Exchanger Installation, Maintenance, Repair

BAHX MRO Solutions

end-to-end sOLUTIONS for brazed aluminum heat exchangers

MIG is an industry leading provider of brazed aluminum heat exchanger (BAHX) installation, maintenance, and repair services. We are an NBIC “R” stamped company for repairs and alterations—both at our shop and in the field.

Our highly trained field service technician teams travel throughout the US, providing a wide range of services including field-based new installations and relocation, routine cleaning and inspection, leak detection and repair, pressure testing and performance evaluation, vibration analysis and balancing, troubleshooting and more—in addition to planned maintenance support and emergency response.

MIG is one of the only companies in the U.S. to provide both brazed aluminum heat exchanger installation services as well as end-to-end field and shop maintenance, testing, and repairs—and has earned a reputation for its rapid emergency repair response times.

CONTACT US

Call us today to speak with one of our BAHX specialists: +1 (317) 870-2400 or click to contact us below:

We Know Brazed Aluminum Heat Exchangers

BAHX HEAT EXCHANGERS EXPERTISE

-

Field ServicesMIG is your one-stop-shop for complete, end-to-end solutions and services supporting the full lifecycle of your brazed aluminum heat exchangers (BAHX). Our highly qualified teams can perform many services directly in the field—minimizing disruption to your operations—including:

- Brazed Aluminum Heat Exchangers (BAHX) New Installations Commissioning & Startup

- Cleaning & Inspection

- Leak Detection & Repair

- Pressure Testing & Performance Evaluation

- Retired BAHX and Related Equipment Removal

- Operational Process Controls

- On-site & Shop BAHX R-Stamp Repairs to NBIC standards

- Oxygen Cleaning

- Preventative Maintenance Programs

- Retrofitting & Upgrades

- On-site & Shop BAHX R-Stamp Modifications

- Plant Relocations

- Plant Shutdowns

- Process Piping, Electrical, Concrete, and Millwright

- Process Analysis and Optimization

- DCS analysis

- Nationwide service

-

Shop ServicesWe are NBIC “R” Stamped company for shop repairs and alterations and can perform a variety of specialty services at shop locations across the U.S. including:

- Certified Welding and Fabrication to NBIC and ASME standards

- Precision Cleaning for Oxygen Service

- Painting & Sandblasting

- Pre-Fab of Piping

- Piping & Valve Modifications

- Steel Cold Box Refurbishing

- Cryogenic piping & Manifolds Fabrication

- Header repair

- Inspection & Test

-

WSPs & PQRsWe maintain multiple WPS’s and PQR’s. Often taken for granted, WSP’s (Welding Procedure Specification) and PQR’s (Procedure Qualification Records) serve as blueprints for performing welds in an efficient, repeatable, and safe manner—that meet with all applicable code requirements and standards.

- Charpy SS

- Stainless Steel to Carbon Steel

- Stainless Steel to Stainless Steel

- Carbon Steel to Carbon Steel

- Aluminum

- Monel

- Inconel

Our WSP’s and PQR’s are your assurance MIG’s seasoned teams deliver welds to the highest standards that ensure maximum life, facility up-time—and safety.

-

Cold Box Installation & MROIn addition to braised aluminum heat exchanger installation and maintenance services, MIG is an industry leading provider of cold box installation, repair, and preventative maintenance.

Our related services include:- Field-based new Cold box installations and relocation

- Cold box repair & maintenance services

- Process piping design, fabrication, installation & repair

- Planned maintenance & turnarounds

- Emergency response

- More

-

Rope AccessMIG's Rope access capabilities allow our technicians to perform work at high elevations and reach braised aluminum heat exchangers and other equipment in areas that can be difficult—and dangerous—to reach.

Rope access also has the benefit of supporting maintenance tasks without disrupting operations in nearby areas. Our team has extensive experience with rope access methods for all of the following tasks:

- Inspection & Testing

- Installation & Construction

- Maintenance & Repair

- Cleaning & Painting

- More

-

Confined Space RescueMIG's confined space rescue team (CSRT) works in a close partnership with its customers to achieve an uncompromised state of safety and productivity.

Our team has extensive experience working inside boilers, tanks, columns, and process vessels—in fact we developed a standby rescue team to support the challenges of this very work.

We can also help you evaluate your needs when it comes to your own OSHA compliant Emergency Response Plan

.png)

FREE Download: Capabilities & Services Flip Book

Our Specialized Services for Essential Industrial Infrastructure - Capabilities & Services Flip Book includes:

- Complete Overview of MIG's Capabilities & Services

- Engineering Services Overview

- Detailed Review of Fabrication Capabilities & Materials

- More

BAHX & COLD BOX SOLUTIONS SPECIALISTS

-webp.webp?width=284&height=219&name=MIG%20Flipbook%20Cover%20w%20Shadow%20(1)-webp.webp)