CLEAN-IN-PLACE SYSTEMS

CIP Systems Engineering, Fabrication, Installation, Repair & Maintenance Services

CIP SYSTEMS & SERVICES

End-to-End CLean-IN-Place Solutions

Maddox Industrial Group (MIG) designs, engineers, fabricates, and installs best-in-class clean-in-place (CIP) system sanitary piping, tanks, control systems, and other components as well as complete, fully automated CIP systems. We can deliver free standing or skid-mounted systems as needed.

CIP systems are one of MIG's specialties and our skilled teams routinely perform new installations, maintenance, upgrades, troubleshooting, and repair of CIP systems, across a variety of industries including food & beverage, dairy, pharmaceutical, and others.

We understand the critical importance of reliable sanitary cleaning processes that protect products from contamination—and maintain cleanliness at levels necessary to meet strict USDA and FDA standards.

CONTACT US

Call us today to speak with one of our Clean-in-Place systems specialists: +1 (317) 870-2400 or click to contact us below:

We Know CIP Systems

HYGIENIC PROCESSING SOLUTIONS

-

Industries ServedMIG provides its clean-in-place systems and services to industry-leading hygienic processing plant owners and operators in a variety of industries including:

- Food

- Beverage

- Dairy

- Breweries

- Distilleries

- Pharmaceutical

- Biotech

-

Sanitary Piping & Tubing

MIG delivers expert sanitary piping & tubing systems engineering, design, fabrication, and installation services, including all piping and tubing, unions & flanges, elbows, tees, and other fittings.

Our related services include:- Design & Engineering

- Fabrication

- Installation

- Maintenance

- Upgrades

- Troubleshooting

- Routine Maintenance

- Repair

- Emergency Repair

- Design & Engineering

-

Orbital WeldingMIG's highly trained, certified welders utilize cutting edge orbital welding technologies to achieve the cleanest, highest-quality, repeatable welds for sanitary service projects. Benefits include:

- Cleanest, Highest-Quality Welds

- Reliable, Consistent Weld Quality

- 'Repeatable' Welds

- Increased Speed

- Greater Efficiency

- Elimination of Internal Surface Oxidation

- Weld Documentation

- Traceability for Quality Control

Orbital welding can also be performed in difficult locations such as restricted access spaces with poor visibility conditions. In hazardous environments, automated systems can be utilized to allow equipment to be set up and then operated from a safe distance.

-

Fabrication for Sanitary ServiceAs part of the TransTech family of companies, MIG can also serve all your custom fabrication needs—including fabrication for sanitary service.

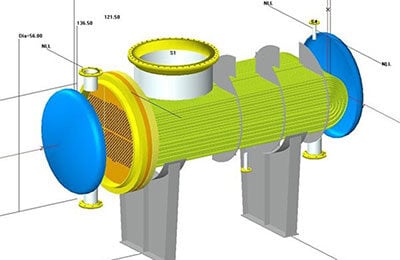

Serving customers nationwide—from facilities boasting over 450,000 ft² of fabrication facility space—MIG designs, engineers, and fabricates outstanding quality Shell & Tube Heat Exchangers, ASME Pressure Vessels, Reactors, Distillation Columns & Towers, Tanks, Piping, and Equipment, in stainless steel, carbon steel, hastelloy & other nickel alloys, and duplex—and offers an array of sanitary service vessel finish options including polished finishes, and pickling & passivation.

Vessel finish options include:

- Hot Rolled (HR) - Grit 100

- Mill Finish (2B)- Grit 240

- No. 3 Grit: 120, RA Range: 40-50

- No. 4 - Grit: 100, RA Range: 15-30 - sanitary, general purpose

- No. 6 - Grit: 240, RA Range: 10-15 - sanitary, highly reflective

- No. 7 - Grit: 320, RA Range: <10 - sanitary, highly reflective, used where product-contact surfaces are critical.

-

O2 CleaningMIG delivers oxygen cleaning (O2 cleaning) services to industry leaders in the pharmaceutical, biotech, chemical, aerospace, electronics industries and others. In addition to our Indianapolis-based Clean Room supporting ASTM G93 Standard Guidelines for O2 cleaning, MIG also serves a wide variety of on-site applications—including performing O2 cleaning services in accordance with facility- and company-specific requirements.

Capabilities & Services include:- On Site O2 cleaning of installation and fabricated pipe, tubing, hoses, valves, and other fittings per ASTM

- 3,000 ft² Cleanroom per ASTM Standard Guidelines of O2 Service at our IN location

- 2 large cleaning tanks that have the capacity to clean full length pipe up to 18” in diameter

- Overhead crane

- O2 Cleaned documentation Provided

- Highly trained and certified personnel

- Over three decades of oxygen cleaning experience

.png)

FREE Download: Capabilities & Services Flip Book

Our Specialized Services for Essential Industrial Infrastructure - Capabilities & Services Flip Book includes:

- Complete Overview of MIG's Capabilities & Services

- Engineering Services Overview

- Detailed Review of Fabrication Capabilities & Materials

- More

INDUSTRIAL SOLUTIONS SPECIALISTS