PROCESS PIPING & TUBING

Custom Process Piping Design, Fabrication

Installation, Maintenance, Repair

PROCESS PIPING & TUBING SOLUTIONS

END-TO-END INDUSTRIAL PROCESS PIPING & TUBING SERVICES

MIG delivers comprehensive industrial process piping and tubing solutions and services across the full plant lifecycle including engineering, fabrication, new installations, upgrades, maintenance, repair, and replacement for both industrial and utility customers.

Serving leaders in the air separation, water/wastewater treatment, food & beverage, pharmaceutical, refining, biofuels, utility, semiconductor industries and others, we deliver complete piping systems including pipes and all interconnected peripherals such as tubing, pressure hoses, gaskets, separators, flanges, valves, instruments, and other components utilized to facilitate and control fluid flow, mixing, separation, distribution, and other functions.

Backed by four decades of experience, MIG's experienced teams bring multidisciplinary skills and expertise to every engagement including proficiency in process, mechanical, structural, electrical, and controls to ensure the highest quality, safe, reliable piping systems in accordance with ASME B31.3 standards.

CONTACT US

Call us today to speak with one of our process piping and tubing specialists: +1 (317) 870-2400 or click to contact us below:

We Know Process

Piping & Tubing

PROCESS PIPING & TUBING SPECIALISTS

-

What Is Process Piping?Process piping refers to any pipework used to transport materials within industrial processing and manufacturing systems.

Process piping is purpose-built, specifically designed to ensure that it meets customer requirements and specification for the application at hand—and that it complies with all related safety and health standards.

A variety of materials can be used for the fabrication of process piping - and material selection is generally based on the materials to be transported.

Because each manufactured product and process is unique, every piping project is accompanied by its own challenges in the fabrication, installation, maintenance and upgrade of these systems.

Our seasoned process piping & tubing specialists have the expertise to meet these challenging and help our customers achieve their piping and tubing goals.

-

Process Piping SystemsMIG performs engineering design, fabrication, installation, maintenance, repair, and upgrades for all of the following process piping systems:

- Steam & Condensate

- Cooling & Service Water

- Compressed Air & Gas

- Instrument & Control

- Hydraulic & Lubrication

- Pneumatic Conveyance

- Petroleum & Pipeline

- High Temperature & Pressure

- Cryogenic

- Food Grade

- Sanitary Tubing

- HVAC

- And More!

-

Capabilities & ServicesMIG's significant capabilities span all aspects of industrial process piping and tubing usage including engineering, fabrication, new installations, upgrades, maintenance, and repair for industrial and utility customers, including:

- Piping Specifications/Development

- Orthographic and Isometric Piping Diagrams

- Bill of Materials (BOM) generation

- Thermal, flexibility, and Dynamic Pipe Stress Analysis

- Process piping design

- Utility piping design

- Volatile and/or flammable gas & liquid piping

- Biogas piping design

- Biofuel piping design

- Pneumatic conveying piping systems

- Process Piping, Tubing, and Piping Modules Fabrication

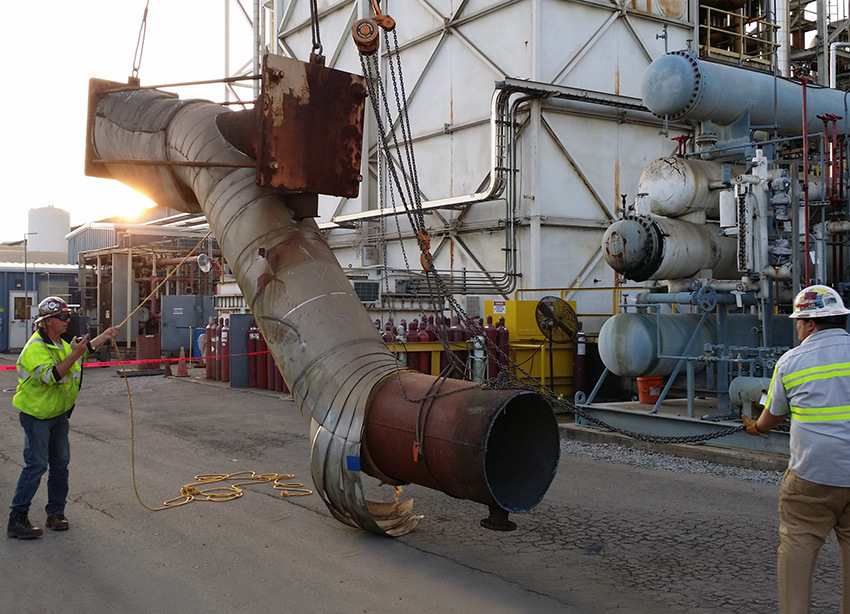

- New Installations

- Precision Laser Alignment

- Certified Welding

- Certified Riggers

- Preventive Maintenance

- Replacement & Repair

- Emergency Maintenance Repairs & Alterations

- All forms of piping materials: stainless steel, carbon steel

- All forms of piping connections: bolt up, welded, Victaulic, threaded, bent tubing, etc.

-

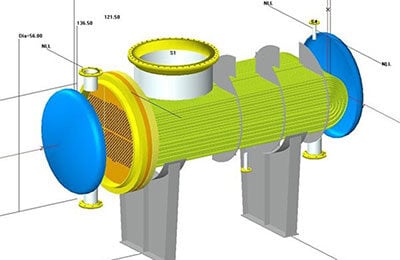

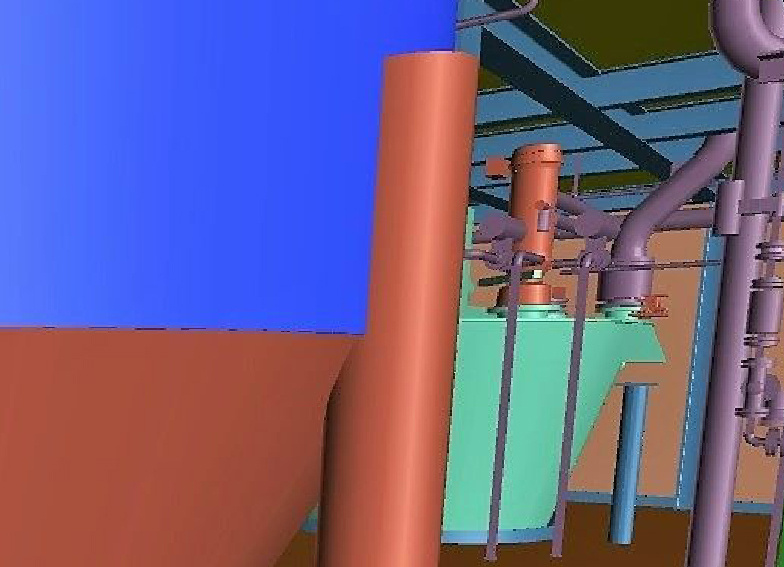

Piping Design SoftwareWhether working independently or in partnership with either customer teams or third-party process engineering firms, MIG's process piping experts design a broad array of projects from new/greenfield facility construction to plant upgrades and overhauls.

MIG has earned a reputation for delivering the highest quality detailed design to our customers' exact specifications, utilizing best-in-class design tools that include the following software:

- MicroStation

- SmartPlant SpoolGen®

- AutoCAD Plant 3D

- And others

-

End-to-End SolutionsBacked by four decades of experience, MIG's expert teams bring multidisciplinary skills and experience to every process piping engagement including process, mechanical, structural, controls, and electrical expertise to deliver safe, reliable piping and tubing systems, designed, built, and installed to ASME B31.3 standards.

Our expert field services teams ensure the continued success of your custom process piping and/or tubing project, to facilitate reliable plant operation—and optimal plant uptime.

For plant owner operators who require a continuous supply of identical tubes across the plant lifecycle, all our process piping, tubing, and pipe modules can be replicated to the identical, original specifications—with any variations if needed—simplifying both reordering and installation processes.

.png)

FREE Download: Capabilities & Services Flip Book

Our Specialized Services for Essential Industrial Infrastructure - Capabilities & Services Flip Book includes:

- Complete Overview of MIG's Capabilities & Services

- Engineering Services Overview

- Detailed Review of Fabrication Capabilities & Materials

- More

INDUSTRIAL SOLUTIONS MRO SPECIALISTS