OXYGEN CLEANING

O2 Cleaning & Cleanroom Services

for Oxygen Service - Per ASTM G93

O2 CLEANING SERVICES

O2 CLEANING FOR OXYGEN RICH ENVIRONMENTS

Maddox Industrial Group (MIG) delivers outstanding in-house and on-site oxygen (O2) cleaning services for reliable removal of contaminants from components, piping, and equipment that will be used in an oxygen or oxidizer systems.

Backed by four decades of experience, our seasoned teams follow stringent oxygen cleaning procedures per ASTM G93 and CGA G-4.1 to ensure adherence to the cleanliness criteria required for each specific application.

From preparation and cleaning, to packaging and delivery—to installation into the related equipment or system(s) if required—we treat every step of the oxygen cleaning process and related services with the utmost care and attention.

We remove an extensive range of contaminants including both organic and inorganic particles and compounds and deeply understand the vital importance of protecting your systems from potential catastrophic consequences of unmitigated ignition.

We remove an extensive range of contaminants including both organic and inorganic particles and compounds and deeply understand the vital importance of protecting your systems from potential catastrophic consequences of unmitigated ignition.

CONTACT US

Call us today to speak with one of our O2 Cleaning specialists: +1 (317) 870-2400 or click to contact us below:

SEE MIG IN ACTION

O2 CLEANING EXPERTISE

-

What Is O2 Cleaning?Oxygen (O2) cleaning is a vital service developed for the removal of flammable contaminants that can potentially facilitate ignition in an oxygen-rich environment.

While oxygen itself is not flammable, it acts as a powerful oxidizer for fuel. By removing contaminants—such as oils, greases, or even dust—from the components, piping, and equipment that support oxygen utilization, the risk for catastrophic fire or explosion can be greatly mitigated.

ASTM G93 is the Standard Practice for oxygen cleaning, but individual applications often vary. Additionally, some owner-operators have developed their own specifications that expand on this standard.

Contact us today to learn how we can help with your Oxygen Cleaning Needs.

-

CapabilitiesIn addition to our Clean Room supporting ASTM G93 Standard Guidelines for oxygen cleaning, Maddox Industrial Group (MIG) also has certified procedures in place for a wide variety of on site applications.

Our capabilities and services include:- On Site O2 cleaning of installation and fabricated pipe, tubing, hoses, valves, and other fittings per ASTM

- 3,000 ft² Cleanroom per ASTM Standard Guidelines of O2 Service at our Indianapolis location

- 2 large cleaning tanks that have the capacity to clean full length pipe up to 18” in diameter

- Overhead crane

- O2 Cleaned documentation

- Trained and certified personnel

- Four decades of O2 cleaning experience

-

IndustriesOxygen is utilized for a variety of applications across an array of industries including the production of steel and other metals, petrochemical, chemicals, specialty chemicals, pharmaceuticals, medical, glass manufacturing, oil & gas processing, and others.

Maddox Industrial Group's highly trained and certified personnel perform outstanding precision cleaning of piping, components, and equipment supporting oxygen service in these industries and others, per ASTM G93 and CGA G-4.1.

-

Fabrication for Sanitary ServiceAs part of the TransTech family of companies, MIG can also serve all your custom fabrication needs—including fabrication for sanitary service.

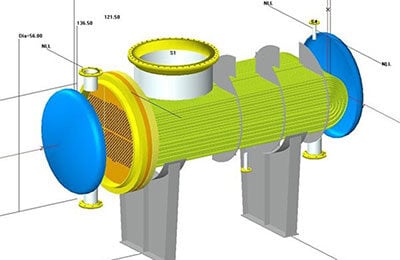

With over 450,000 ft² of fabrication facility space serving customers from locations across the U.S., MIG can deliver the highest quality custom fabricated ASME pressure vessels, TEMA heat exchangers, reactors, distillation columns & towers, tanks, and equipment, in stainless steel, carbon steel, hastelloy & other nickel alloys, and duplex—and provide an array of sanitary service vessel finish options including pickling & passivation, and polished finishes.

Vessel finish options include:

- Hot Rolled (HR) - Grit 100

- Mill Finish (2B)- Grit 240

- No. 3 Grit: 120, RA Range: 40-50

- No. 4 - Grit: 100, RA Range: 15-30 - sanitary, general purpose

- No. 6 - Grit: 240, RA Range: 10-15 - sanitary, highly reflective

- No. 7 - Grit: 320, RA Range: <10 - sanitary, highly reflective, used where product-contact surfaces are critical.

-

ASTM G93ASTM G93 is the Standard Practice, set forth by the American Society for Testing & Materials (ASTM), for Cleanliness Levels and Cleaning Methods for Materials and Equipment Used in Oxygen-Enriched Environments.

These cleaning procedures, commonly referred to as Oxygen Cleaning or O2 Cleaning, follow specific processes for the cleaning of equipment, pipework, and peripherals used in the storage, transport. and utilization of oxygen.

MIG's highly trained and certified personnel perform outstanding O2 cleaning of piping, tubing, hoses, valves, and components, supporting oxygen service.

Learn More about ASTM G93 here.

.png)

FREE Download: Capabilities & Services Flip Book

Our Specialized Services for Essential Industrial Infrastructure - Capabilities & Services Flip Book includes:

- Complete Overview of MIG's Capabilities & Services

- Engineering Services Overview

- Detailed Review of Fabrication Capabilities & Materials

- More

INDUSTRIAL SOLUTIONS SPECIALISTS