AIR SEPARATION

Turnkey MRO Services

Repair, Upgrades, Relocation

AIR SEPARATION MRO Solutions

ASU Services for Reliability & Performance

Maddox Industrial Group (MIG) provides specialized services for air separation units (ASU’s)—a critical component of essential industrial infrastructure—across a wide array of industries including healthcare, medical, manufacturing, transportation, and others.

MIG and has earned a reputation for its unrivaled expertise, responsiveness, safety record, and capabilities, and provides its turnkey services to the largest Air Process companies in the world including Linde, Praxair, Air Products, Matheson, Messer, Air Gas, and Air Liquide.

MIG’s project management expertise, hands-on team, and time-and-material project transparency make it unique in the marketplace—and we’ve established a reputation for consistently delivering cost-effective, innovative solutions that support and improve air separation plant efficiency and reliability.

CONTACT US

Call us today to speak with one of our Air Separation specialists: +1 (317) 870-2400 or click to contact us below:

We Know Air Separation

AIR SEPARATION PLANT EXPERTISE

-

CapabilitiesIn addition to air separation equipment and systems installation, maintenance, and repair, MIG offers significant capabilities in process piping fabrication; tanks, vessels, & equipment fabrication; installation and construction management; plant upgrades and turnarounds; electrical and process controls; welding and fabrication; precision cleaning for oxygen service; pressure testing, crane work, civil work, and more—all backed by deep experience in the industrial gas industry.

We’ve established a reputation for consistently delivering cost-effective, innovative solutions that support and improve air separation plant efficiency, reliability—and profitability.

-

Cold Box Installation & MROMIG is an industry leading provider of cold box installation, repair, and preventative maintenance services. We are an NBIC “R” Stamped company for repairs and alterations both at our shop and in the field. Our services include:

- Field-based new installations and relocation

- Repair & maintenance projects on cold boxes, brazed aluminum heat exchangers (bahx), ASME pressure vessels

- Process piping design, fabrication, installation & repair

- Highly trained and experienced rope access teams

- Planned maintenance & turnarounds

- Emergency response

- More

-

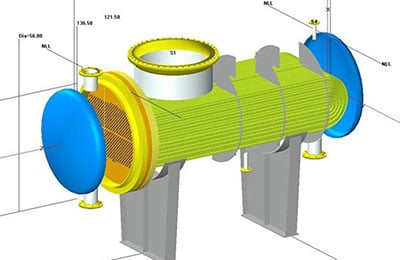

BAHX Installation & MROMIG delivers outstanding turnkey braised aluminum heat exchanger (BAHX) installation, preventative maintenance, and repair services and changeouts to support optimal cryogenic processes.

With four decades of experience, our seasoned teams have the experience and expertise to optimize temperature and pressure capabilities and maximize performance across the plant lifecycle.

MIG is one of the only companies in the U.S. to provide end-to-end field and shop maintenance, testing, and repairs of BAHX heat exchangers—and has earned a reputation for meeting quick response parameters in emergency repair settings.

Learn more about our braised aluminum heat exchanger installation, maintenance, and repair services here.>

-

Best-in-Class SolutionsAir separation plants (ASUs) are used to separate atmospheric air into its primary components, including nitrogen, oxygen, and argon, along with smaller amounts of other gases.

ASUs commonly utilize fractional distillation - also called cryogenic distillation - to deliver industrial gases including nitrogen, oxygen and often co-produce argon, CO2 and hydrogen.

Non-cryogenic air separation plants include membrane, pressure swing adsorption (PSA) and vacuum pressure swing adsorption (VPSA).

MIG delivers best-in-class solutions for all air separation plant types, including both cryogenic and non-cryogenic ASUs and can help you determine the optimal solution for your operations. Contact us today to learn more.

-

QualificationsWe attribute our success to our experience in the industrial gas industry.

- WPS, PQR and Charpy Certified in stainless steel, carbon steel, aluminum, monel, or iconel

- National & international project experience

- Highly skilled, versatile teams

- Tenured professionals/technical staff.

- 60 FT qualified staff

- OSHA 10 & 30 trained.

- Proven project execution abilities.

- State-of-the-art fabrication shop, paint booth, storage, clean room, confined space rescue center

- Through our network of TransTech family companies we're able to leverage over 300,000 sq. feet of fabrication facility space nationwide, including TX, NC, IN, and OR locations, to support rapid, efficient project delivery

- Strong emphasis on safety – EMR .68; 'A' rating with ISNetworld

FREE Download: Capabilities & Services Flip Book

Our Specialized Services for Essential Industrial Infrastructure - Capabilities & Services Flip Book includes:

- Complete Overview of MIG's Capabilities & Services

- Engineering Services Overview

- Detailed Review of Fabrication Capabilities & Materials

- More

AIR SEPARATION SOLUTIONS SPECIALISTS