WELDING & FABRICATION

NBIC; ASME U, U2, U3, and S;

TEMA Class R, C & B; API-620/650/660; AWS

WELDING & FABRICATION SERVICES

Custom INDUSTRIAL WELDING & FABRICATION SERVICES

MIG’s state-of-the-art fabrication facility brings together cutting-edge equipment and highly-skilled, experienced engineering and fabrication teams, offering outstanding quality engineered and fabricated solutions to clients in the air separation, water/wastewater treatment, food & beverage, pharmaceutical, specialty chemical, petrochemical industries and others.

As a TransTech family company we leverage all company facilities, capabilities, and locations across the U.S. to execute and deliver projects cost-effectively, efficiently and to optimal schedules. Our shared capabilities include:

- ASME U, U2, U3, and S

- TEMA class R, C & B

- NBIC certifications

- API-660, API-650, API-620

- UL-142 single and double wall

- NFPA-58, NFPA-22

- WPS, PQR and Charpy Certified in stainless steel, carbon steel, aluminum, monel, or iconel

CONTACT US

Call us today to speak with one of our welding & fabrication specialists: +1 (317) 870-2400 or click to contact us below:

Welding & Fabrication

Specialists

WELDING & FABRICATION SPECIALISTS

-

CapabilitiesMIG offers cutting edge welding and fabrication capabilities to serve all your custom fabricated, specialized tanks, vessels, piping, and equipment needs - from fabrication, to R-stamp modification & repair, and more, including:

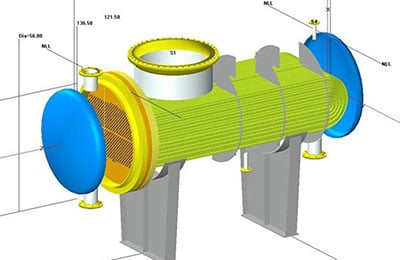

- Shell & Tube Heat Exchangers

- ASME Pressure Vessels

- Reactors

- Distillation Columns & Towers

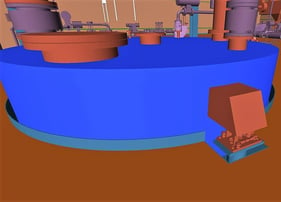

- API Storage Tanks

- Specialized Tanks - Mixing & Batch Tanks, Feed Tanks, More

- Process Piping & Tubing

-

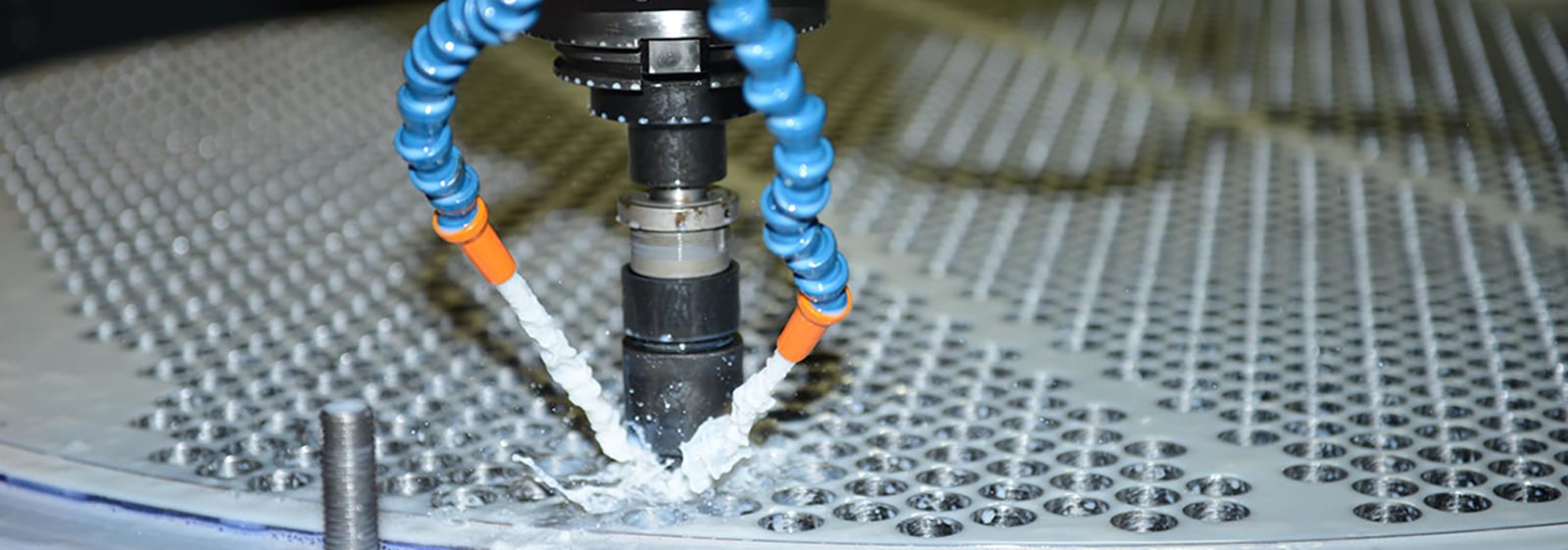

Orbital WeldingMIG's highly trained teams utilize cutting edge mechanized, orbital welding technologies to deliver quality, accuracy - and speed - to your welded projects. We offer orbital welding for all your critical welding needs including sanitary service and other specialized applications that demand the highest-quality, consistent, repeatable welds. Benefits include:

- Increased Speed & Efficiency

- Consistent, Excellent Weld Quality

- Cleanest Welds

- Eliminates Internal Surface Oxidation

- Weld Documentation, Traceability for Quality Control

Orbital welding can also be utilized in difficult environments including restricted access spaces with low visibility. Automation allows welding equipment to be set up and then operated from a safe distance when needed.

-

Engineering & Design SoftwareOur highly-trained engineering professionals are experienced in the following design & engineering software:

- AutoCAD Plant 3D

- HTRI: Thermal analysis of TEMA / Shell & Tube Heat Exchangers

- COMPRESS: Mechanical design of Pressure Vessels, Reactors, and TEMA / Shell & Tube Heat Exchangers

- AME Tank - Rapid configuration, design, and detailing of above-ground storage tanks

- CUSTOM Our own, custom programs developed by our own, expert, in-house teams for the efficient creation of Bill of Materials (BOM) and for providing highly accurate Customer Quotations

- Aspen Shell and Tube (mechanical & thermal)

- PVElite

- Nozzle Pro for finite element analysis

(FEA) - Inventor

-

Process Piping & TubingMIG delivers expert fabrication, installation, maintenance, repair, upgrades, and replacement of industrial process piping and tubing systems used to convey hot and cold liquids, water, steam, and other fluids and gases - along with the installation of all related equipment and fixtures that store, pump, regulate, measure, and distribute these liquids and gases.

Our services span all you related needs including: piping, tubing, valves, pumps, motors, and other mechanical equipment necessary for safe and efficient operation.

Learn more about our process piping & tubing installation & maintenance services here.

-

WPSs and PQRsWe maintain multiple WSPs (Welding Procedure Specification) and PQRs (Procedure Qualification Records). These procedures serve as blueprints for performing welds in an efficient, repeatable, and safe manner—that meet with all applicable code requirements and standards.

- Charpy SS

- Stainless Steel to Stainless Steel

- Stainless Steel to Carbon Steel

- Carbon Steel to Carbon Steel

- Aluminum

- Monel

- Inconel

Our seasoned teams diligently adhere to our WSP’s and PQR’s. You can rest assured knowing we execute welds to the highest quality standards that ensure maximum life, facility up-time—and safety.

-

O2 CleaningMIG delivers expert oxygen cleaning services for the reliable removal of contaminants from components, piping, and equipment that will be used in an oxygen or oxidizer systems. Our O2 cleaning capabilities & services include:

- 3,000 ft² Cleanroom per ASTM Standard Guidelines at our IN location

- 2 large cleaning tanks with the capacity to accommodate full length pipe of up to 18” diameter

- Overhead crane for ease of handling, safety, and speed

- On Site O2 cleaning of installation and fabricated pipe, tubing, hoses, valves, and other fittings per ASTM G93

- 'O2 Cleaned' documentation provided

- Highly-trained, certified personnel

- Four decades of O2 cleaning experience

In addition to our Clean Room, we also have certified procedures in place for a wide variety of on-site applications.

-

End-to-End ServicesMIG delivers comprehensive, end-to-end project delivery services from engineering design, fabrication, and test, to delivery, installation, commissioning & startup.

But it doesn't end there - once your project is complete we're there to assist with operator training through ongoing preventative maintenance, repair, overhaul, replacement, relocation-and even final decommissioning, demolition, and removal! Our Services Include:

- Engineering Design.

- Fabrication & Test

- Sandblast & Coating

- Valving & Instrumentation

- Project Management

- Store & Ship / Vessel Staging

- Heavy Hauling & Installation

- Commissioning & Startup

- Operator Training

- Preventative Maintenance

- Repair

- Modifications & Upgrades

- Relocation

- Decommissioning

FREE Download: Capabilities & Services Flip Book

Our Specialized Services for Essential Industrial Infrastructure - Capabilities & Services Flip Book includes:

- Complete Overview of MIG's Capabilities & Services

- Engineering Services Overview

- Detailed Review of Fabrication Capabilities & Materials

- More