SHELL & TUBE HEAT EXCHANGERS

Custom Shell & Tube Heat Exchanger Engineering, Design, & Fabrication Services

HEAT EXCHANGER FABRICATION SERVICES

CUSTOM SHELL & TUBE HEAT EXCHANGERS

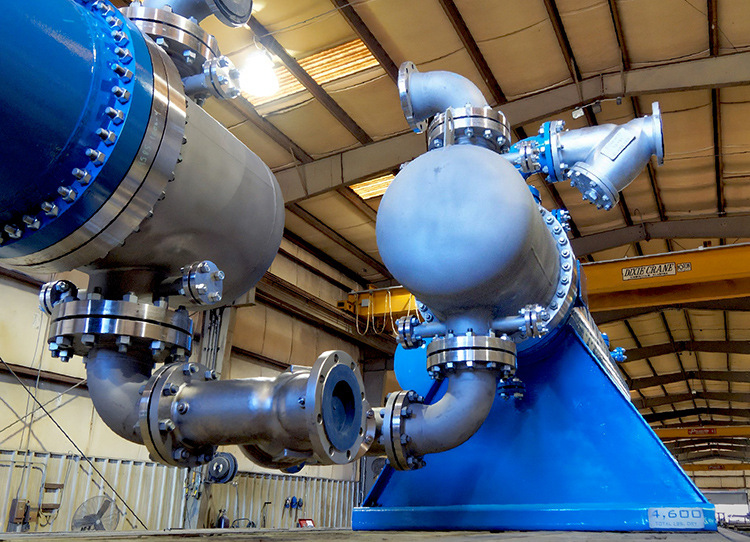

Maddox Industrial Group (MIG) provides custom shell and tube heat exchanger engineering and fabrication solutions for air separation, food & beverage, pharmaceutical, refining & biofuels, and other process industries.

We bring decades of experience to every project, with the expertise to size, design and fabricate your heat exchanger to the highest standards of quality and performance, for maximum efficiency—and ROI

We bring decades of experience to every project, with the expertise to size, design and fabricate your heat exchanger to the highest standards of quality and performance, for maximum efficiency—and ROI

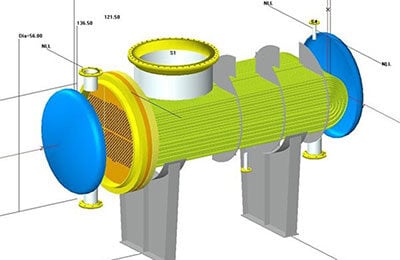

Our seasoned team of mechanical and thermal design engineers utilizes advanced Compress and HTRI thermal design software to achieve the optimal custom solution to meet your specific process requirements.

As a TransTech family company we leverage all company facilities and locations across the U.S. to execute and deliver projects cost-effectively, efficiently and to optimal schedules.

As a TransTech family company we leverage all company facilities and locations across the U.S. to execute and deliver projects cost-effectively, efficiently and to optimal schedules.

CONTACT US

Call us today to speak with one of our welding & fabrication specialists: +1 (317) 870-2400 or click to contact us below:

Heat Exchanger Fabrication

Specialists

HEAT EXCHANGER SPECIALISTS

-

Designed for Reliability:We know the importance of heat exchanger reliability and the necessity for safe, effective solutions that provide for easy cleaning, inspection, and routine maintenance to ensure safe, reliable operations—and long equipment life.

Because of this, all our heat exchangers are designed, fabricated, inspected, and rigorously tested to meet with the most stringent pressure, temperature and mechanical design standards including:- ASME 3A for sanitary dairy, food and personal care applications

- ASME BPE (bioprocessing equipment) for pharmaceutical applications

- ASME BPVC – Section VIII, Div 1

- FDA

-

Every ApplicationWe deliver world-class solutions to meet all your heat exchanger needs, including:

- Chillers / Coolers

- Condenser

- Crystalize

- Dryers

- Evaporators

- Fuel Heaters

- Heat Sink

- Intercoolers

- Preheaters

- Re-boilers

- Refrigeration

- Rising Film Evaporators

- Steam Generators

- Super Heaters

- Vacuum Condensers

- Vaporizers

- Heaters

-

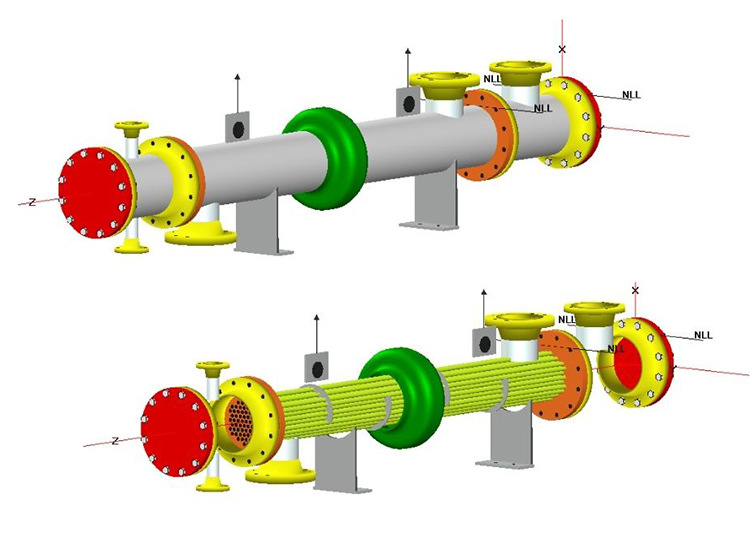

CapabilitiesWe manufacture a broad variety of heat exchanger types with options and characteristics to suit virtually any purpose including:

- Single Pass, Multi Pass

- Floating & Fixed Head Options

- Parallel-Flow, Counter-Flow

- Regenerative & Non-regenerative Configurations

- Single & Double Tubesheet

- With & Without Phase Change

- High Purity Surface Finishes

- Lined & Unlined Flanges

- Standalone Units, Parallel Units

- Standard Grade, Sanitary/Food Grade & Pharmaceutical Grade Options

- Insulation Jackets

- Expansion Joints

-

MetallurgyMIG fabricates shell & tube heat exchangers from a variety of metals including:

- Carbon Steel

- Stainless Steel

- Hastelloy

- Other Nickel Alloys

- Duplex

-

State-of-the-Art CNCWhen you entrust a heat exchanger project to us, we employ cutting edge tools and technologies to deliver the highest quality results.

Utilizing state-of-the-art Quickmill milling and drilling machinery provides outstanding, close tolerance machining of tubesheets used in the manufacture of our custom Shell & Tube Heat Exchangers - improving the quality and performance of every heat exchanger we produce.

.png)

FREE Download: Capabilities & Services Flip Book

Our Specialized Services for Essential Industrial Infrastructure - Capabilities & Services Flip Book includes:

- Complete Overview of MIG's Capabilities & Services

- Engineering Services Overview

- Detailed Review of Fabrication Capabilities & Materials

- More

INDUSTRIAL SOLUTIONS SPECIALISTS