SKIDDED EQUIPMENT

Modular Equipment & Piping Skids - Engineering & Fabrication Services

SKIDDED EQUIPMENT SERVICES

SKID-MOUNTED, PACKAGED EQUIPMENT

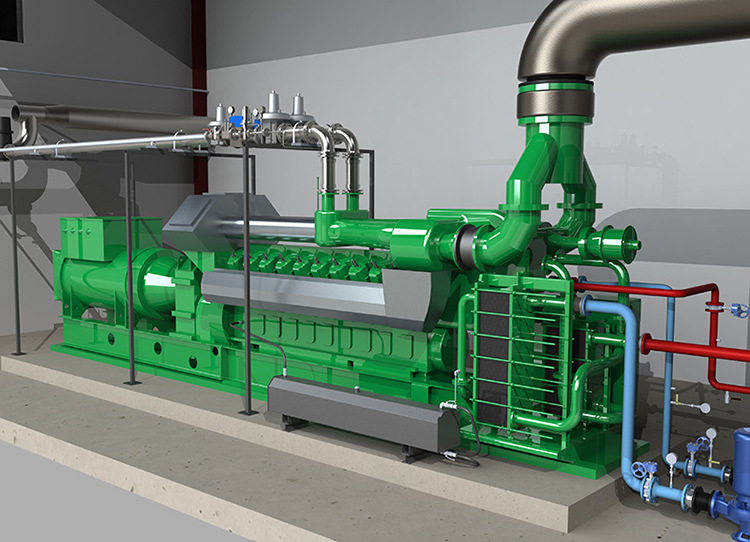

Maddox Industrial Group offers packaged skidded equipment for a broad range of applications, designed to accommodate a complete process or system—including all necessary equipment, piping, electrical wiring, and controls—into a single frame.

Our high-performance skid systems are engineered-to-order packages that deliver seamless, plug-and-play functionality. All systems are entirely preassembled, fully optimized, and tested prior to shipment—arriving to your facility ready for immediate installation and equipped for seamless tie-in to your process.

Skid-mounted solutions offer easier transport, rapid installation, and faster startup than traditional onsite construction methods—saving you time and money while delivering a host of other benefits.

CONTACT US

Call us today to speak with one of our welding & fabrication specialists: +1 (317) 870-2400 or click to contact us below:

We Know Skidded Equipment

SKIDDED EQUIPMENT SPECIALISTS

-

EngineeringMIG's professional engineers serve a variety of disciplines including piping, mechanical, civil, structural, discrete and process engineering, electrical, instrumentation, and controls.

Our seasoned teams can assist you in all aspects of your skidded equipment project—from defining project requirements to specification of all equipment and materials, to ensuring all applicable code requirements are met.

Learn about our engineering services here.

-

Fabrication

Our expert fabrication teams have the ability to engineer, fabricate, integrate, and automate your custom packaged/skidded equipment solution to your exact specifications.

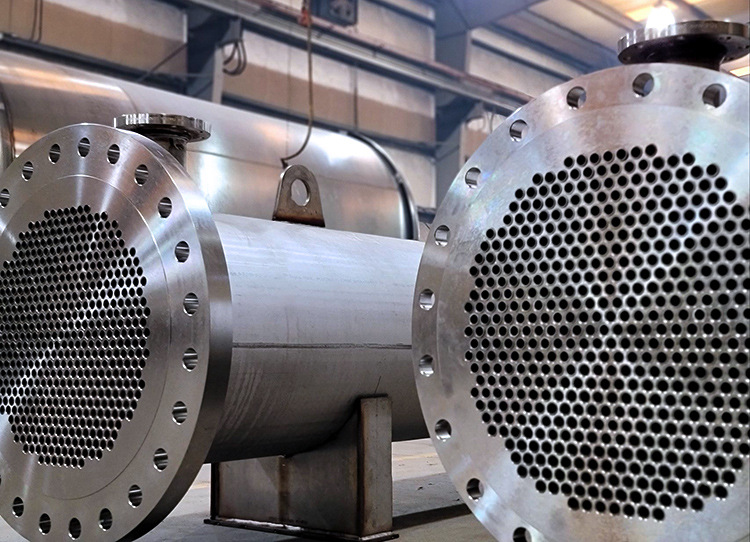

Unlike many competitors, we have the ability to fabricate your tanks, process piping, pressure vessels, heat exchangers, distillation columns, and more in-house, to your exact specifications, so you always know what you’re getting – and get exactly what you want.

Learn about our welding & fabrication solutions here.

-

CapabilitiesWe deliver world-class solutions to meet all your skidded, packaged equipment needs. As a member of the TransTech family of companies, we're able to leverage fabrication facilities at locations across the U.S. to execute and deliver skidded equipment projects cost-effectively, efficiently and to optimal schedules. Our capabilities include:

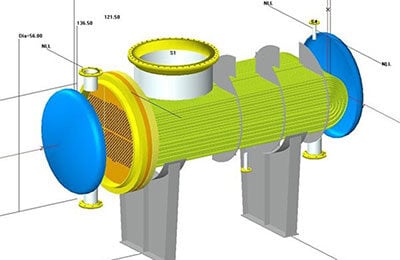

- Tanks & Equipment Fabrication, including ASME pressure vessels, heat exchangers, reactors, distillation columns, tanks, more.

- Process piping & tubing fabrication

- Design engineering, drafting, 3D modeling

- Electrical, Instrumentation & Controls Engineering

- Systems integration

- Mechanical assembly

- Procurement

- Construction

- Pumps & motors

- Connections/

fittings - Custom weldments

- Instrumentation

- Automation & controls

- Painting & Coating

- Integration with existing equipment

- Automation

- Metering

- Insulation

- Expansion Joints

- Logistics & Heavy Hauling

- Installation

- Commissioning & Startup

-

ApplicationsWe manufacture an extensive range of skidded equipment with features and options to suit virtually any purpose. including the following applications—and more:

- Absorber Vessel Systems

- Air & Gas Blowers

- Air & Gas Compression

Skids - Biofuel

- Biogas Cleaning

- Biogas Treatment

- Blower Packages

- Chemical Blending

- Chemical Dosing

- Chemical Processing

- CO2 Removal Systems

- Cooling Skids

- Dehy Packages

- Filtration Skids

- Fuel Blending

- Fuel Transfer

- Gas Conditioning Skids

- H2S Removal systems

- Heat Exchanger Skids

- HVAC

- LFG, RNG

- Membrane systems

- Modular Pipe Skids

- Particulate Removal

- Pilot Plants

- Post-treatment

- Power Generation

- Pre-treatment

- Process Skids

- Pump Skids

- Regulator Skids

- NGL, LPG, LNG

- Tank Level Control

- Transfer Skids

- Treatment Skids

- Vacuum Gas Blowers

- Water treatment skids

-

Logistics & Heavy HaulingBacked by four decades of experience, MIG’s logistics services span all aspects of heavy hauling and delivery—including obtaining all required city, state, and county permits.

Utilizing a select network of heavy equipment transport providers that is limited to the most experienced heavy hauling companies in the business, we can ensure the right equipment is assigned to your delivery— including specialized trailers specifically designed to haul loads that exceed standard weights & dimensions.

With over 100 acres of on-site storage space available across our fabrication locations nationwide, we can also provide the convenience of staging your packaged equipment skids until needed.

Let MIG handle all the details of your delivery and put your mind at ease knowing your equipment skids will arrive in excellent condition—on time, and on budget.

-

InstallationMIG delivers expert skid installation services for both in-plant and on-site applications—from freight and offloading through startup and operator training, and more.

Our end-to-end services include:- Site excavation and grounds work including site survey, grading & drainage for outdoor installations

- Permitting & environmental compliance

- Construction management

- Staging & logistics

- In-line installation

- Interconnecting piping

- Cleanroom tenting

- Equipment & systems integration

- Piping & upgrades

- Tie-in points for future expansion

- Utility tie-in

- Control system updates

- Equipment calibration & test

- Start-up

- Operator Training

- Ongoing maintenance, upgrades, repair

.png)

FREE Download: Capabilities & Services Flip Book

Our Specialized Services for Essential Industrial Infrastructure - Capabilities & Services Flip Book includes:

- Complete Overview of MIG's Capabilities & Services

- Engineering Services Overview

- Detailed Review of Fabrication Capabilities & Materials

- More

INDUSTRIAL SOLUTIONS SPECIALISTS