AIR SEPARATION

PLANT MRO

SPECIALISTS

TURNKEY INSTALLATION,

MAINTENANCE, REPAIR,

UPGRADES, RELOCATION

INDUSTRIAL PROCESS PIPING

TURNKEY INSTALLATION,

MAINTENANCE, REPAIR,

UPGRADES, RELOCATION

Industrial Solutions Specialist

Design/Build • Maintain • Repair • Optimize • Re-life • Expand • Relocate • Decommission

ACHIEVE PEAK PLANT PERFORMANCE

Backed by over three decades of experience, MIG leads the industry in providing outstanding engineering, fabrication, construction, cryogenic, and mechanical solutions & services to support every aspect of production/processing, storage, transfer, and utilization of industrial gases and liquids.

Our Innovative, cost-effective solutions:

- Improve plant operational performance & reliability

- Increase plant availability

- Extend asset lifetime

- Maximize ROI

WORK WITH MIG

INDUSTRIAL MAINTENANCE SERVICES SPECIALISTS

.png)

FREE Download: Capabilities & Services Flip Book

Our Specialized Services for Essential Industrial Infrastructure - Capabilities & Services Flip Book includes:

- Complete Overview of MIG's Capabilities & Services

- Engineering Services Overview

- Detailed Review of Fabrication Capabilities & Materials

- More

INDUSTRIES

Specialized Services Spotlight

Confined Space Rescue

MIG's Confined Space Rescue Team (CSRT) works in a close partnership with its customers to achieve an uncompromised state of safety and productivity.

Our team has extensive experience working inside boilers, tanks, columns, and process vessels—in fact we developed a standby rescue team to support the challenges of this very work.

We can also help you evaluate your needs when it comes to your own OSHA compliant Emergency Response Plan.

Specialized Services Spotlight

Rope Access

MIG's Rope access capabilities support both the safety and speed with which workers can perform their work in difficult locations - many times with minimal impact on other operations in nearby areas. Our team has extensive experience utilizing rope access methods for all of the following tasks:

- Inspection & Testing

- Construction, Maintenance & Repair

- Cleaning & Painting

- Facilities Management & Building Services

- More!

Specialized Services Spotlight

BAHX Installation, Maintenance & Repair

MIG is an industry leading provider of brazed aluminum heat exchanger (BAHX) and Cold Box installation, repair, and maintenance services.

We are an NBIC “R” Stamped company for Repairs and Alterations both at our shop and in the field - and we're one of the only companies in the U.S. to provide end-to-end field and shop maintenance, testing, and repairs of BAHX heat exchangers.

Specialized Services Spotlight

EMERGENCY REPAIRS & MODIFICATION

Our expert maintenance and repair personnel are ready to respond to unexpected failure of your mission critical equipment, including cold boxes, brazed aluminum heat exchangers, ASME pressure vessels, process piping, distillation columns, and other related equipment.

We are an NBIC “R” Stamped company for repairs and alterations both in the field and at our shop and we've earned a reputation for meeting quick response parameters in emergency repair settings.

Specialized Services Spotlight

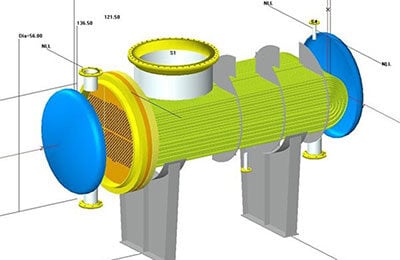

ASME FABRICATION & INSTALLATION

MIG’s state-of-the-art fabrication facility brings together cutting-edge equipment and highly-skilled, experienced engineering and fabrication teams, offering the highest quality custom engineered and fabricated products for a wide range of applications.

As a TransTech family company we leverage all facilities and locations across the U.S. to execute and deliver projects cost-effectively, efficiently and to optimal schedules—including the engineering, design, and fabrication of TEMA heat exchangers, distillation columns & towers, ASME pressure vessels, reactors, API storage tanks, and more.

What Makes Us Different?

-

Top Rated for SafetyMIG is dedicated to promoting a safe, healthy workplace and to protecting communities and the environment in which we work. Our highly trained teams perform to the highest standards with a goal zero approach: zero incidents, zero accidents, and zero environmental releases.

We strive for continuous, measurable improvement of safety performance across all functional areas and our management teams set standards and procedural requirements to protect workers, partners and customers by eliminating the opportunity for potential hazards - before they occur.

-

In-House FabricationMIG's state-of-the-art fabrication facility brings together cutting-edge equipment, resources, and highly-skilled, experienced engineering and fabrication teams, offering the highest quality fabricated TEMA heat exchangers, ASME pressure vessels, distillation columns & towers, reactors, tanks, piping, and equipment to clients in the air separation, water/wastewater treatment, food & beverage, pharmaceutical, refining & biofuels, and semiconductor manufacturing industries and others.

As part of the TransTech family of companies, we are able to leverage fabrication facilities and locations across the U.S. to deliver projects cost-effectively, efficiently and to optimal schedules.

-

24-7 Emergency Service24-7 Emergency Response Service

Our Team Is Standing By - If you have a confined space emergency contact us now:

Cory Martin: (+1) 317-370-0341

Jessie Carter:(+1) 317-716-2233

Our seasoned team has extensive experience working inside boilers, tanks, columns & towers, cold boxes, and process vessels. We have long understood the necessity of a standby rescue team trained specifically to serve related incidents which can make the difference between life or death.

MIG can also assist you in the development of an OSHA compliant Emergency Response Plan for your facilities. Learn more.

-

National & International Service TeamsAs a TransTech company, we are able to leverage all company capabilities, fabrication facilities, service teams, and locations to execute and deliver projects cost-effectively, efficiently and to optimal schedules—across the U.S. and abroad.

The company's divisions include Energy, Fabrication, Services, Renewables, and Cryogenic Solutions, with a focus on gas and liquids processing, storage, transfer, and utilization.

Our integrated, specialized teams work individually or jointly, based on customer needs, to deliver a broad array of engineering, fabrication, construction, maintenance, and operations projects nationwide and abroad.

-

Four Decades of ExperienceFounded in 1984, Maddox Industrial Group was established to support both the public utility and private industrial markets.

Today, MIG is a full-service industrial contractor offering specialized engineering, electrical and process controls, fabrication, and construction solutions to support essential industrial infrastructure, with close to four decades of experience.

We also offer extensive field service capabilities including equipment installation and replacement, vessel and equipment maintenance, R-stamp repair, electrical upgrades and retrofit, and confined space rescue.

Our Company

CAREERS

Join a team that is continually breaking new ground and pushing boundaries in project development, engineering construction, site installation, operations, maintenance & repair - delivering solutions to our customers across all phases of the project delivery chain.

HSE

We perform our work to the highest safety standards with a goal zero approach: zero incidents, zero accidents, and zero environmental releases. Our goal is to eliminate day-to-day perils - before they happen.

MISSION & VALUES

At Maddox Industrial Group, we ensure that T.R.U.S.T. is the center point of how we do business - learn about the MIG Way!